Speed, reliability and efficiency together with maximum precision!

Especially in the mid and high-volume production of precision turning parts with a diameter of 2 - 100 mm, we offer a high vertical range of manufacture. We produce the most complex of shapes in specially set up machining processes, in a production area of over 8,000 m². For our turning parts and assemblies, we process all machinable materials. These include high-grade steels, free cutting steels, bronze, copper, aluminium, titanium, as well as special alloys and plastics. Our in-house tool shop increases the production process reliability and ensures fast response times.

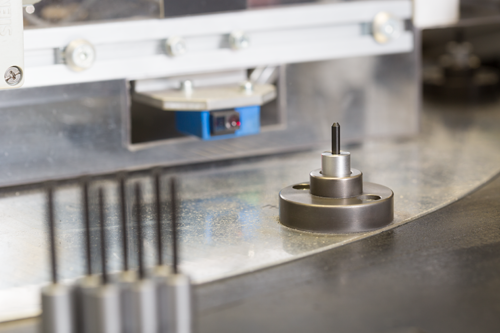

At EBERLE, the most modern machine generation at any one time is utilized. Whether longitudinal lathes from Star and Tornos, CNC fixed head automatic lathes from Index, CNC multi-spindle lathes from Index and Tornos, rotary transfer machines, various finishing machines, slide grinding machines and blast machines.

The machine pool is supplemented by our assembly facility. Here we put assemblies together manually or automatically. All processes are safeguarded with appropriate test procedures. With these versatile setups, we are in a position to offer our customers the right technology for almost all types of turning parts.

Versatility is our strength!

The possibility of subsequent processing in the form of surface finishing with mechanical, electroplating or thermal processes is a further expression of our versatility, which we will retain in the future – by constant enhancement of our production processes.

Processing offered: electroplating, heat treatment, electropolishing, sanding, tempering, hardening, laser labelling, laser welding, ECM and other deburring technologies, plunge and wire EDM, varnishing and many more.